A Deep, Practical, First-Principles Guide for Modern Dyehouses

Why This Topic Matters

Reactive dyes remain the backbone of cotton coloration—over 55–60% of global cotton is dyed with them. Yet most mills still rely on legacy recipes, struggle with shade reproducibility, face high salt/alkali costs, and encounter persistent issues: tailing in softflow, barre, low fixation, high rewash demand, and elevated COD/BOD loads.

Understanding all dyeing methods—not just the recipes but the chemistry, mechanisms, and operational consequences—is what separates an average dyehouse from a world-class facility.

This blog gives you an industrial, mechanism-level, compliance-aware guide to every major method of reactive dyeing, when to use it, its advantages/limitations, and the process windows that matter.

How Reactive Dyeing Works

Reactive dyes bond covalently with cellulose.

Two reactions dominate:

| Reaction | Mechanism | Impact | Risk |

|---|---|---|---|

| Fixation (Substantive + Reactive) | Dye–Cellulose covalent bond under alkaline pH | Fastness, depth, efficiency | Competes with hydrolysis |

| Hydrolysis | Dye reacts with water instead of fiber | Exhaustion drops | Leads to wash-off load, COD/BOD |

The entire dyeing strategy—salt addition, alkali timing, temperature control—is simply managing three forces:

- Affinity (salt controls migration/exhaustion)

- Reactivity (alkali controls fixation)

- Hydrolysis rate (temperature & pH control)

Different dyeing methods manipulate these three variables differently.

The 7 Major Methods of Reactive Dyeing of Cotton

Here is the industrial landscape.

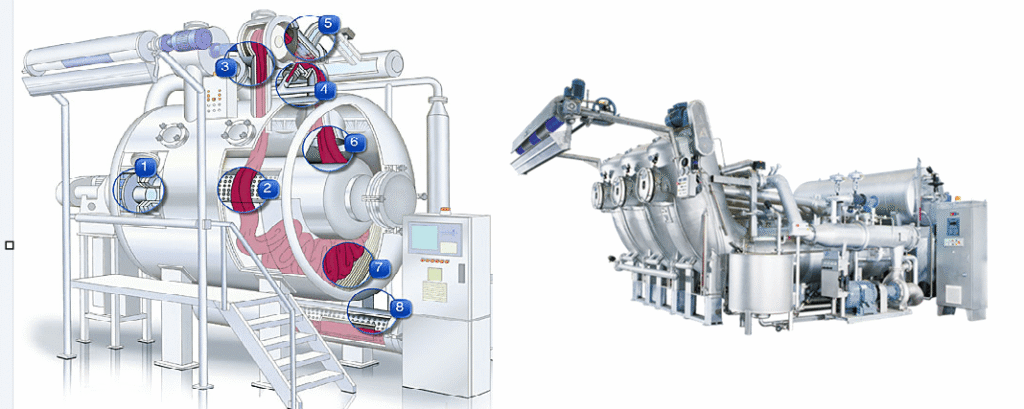

Method 1: Exhaust Dyeing (Soft Flow / Jet)

Where It Works Best

Knits, hosiery, yarn packages, delicate structures that demand good migration.

How It Works (Mechanism)

Salt drives exhaustion → alkali initiates fixation → temperature controls migration vs. aggregation.

Typical Process Window

| Parameter | Range |

|---|---|

| M:L | 1:6 to 1:12 |

| Temp | 60–80°C |

| Salt | 40–80 g/L (depending on dyestuff class) |

| Alkali | 5–20 g/L soda ash (liquid caustic for darks) |

Advantages

- Excellent leveling

- Good penetration in knits

- Flexible for small lots

Limitations

- Long process

- High salt + high wash-off → high COD/BOD

- Dye hydrolysis during long alkali hold

Best For

- Premium knits

- Hosiery

- Dark shades with high migration need

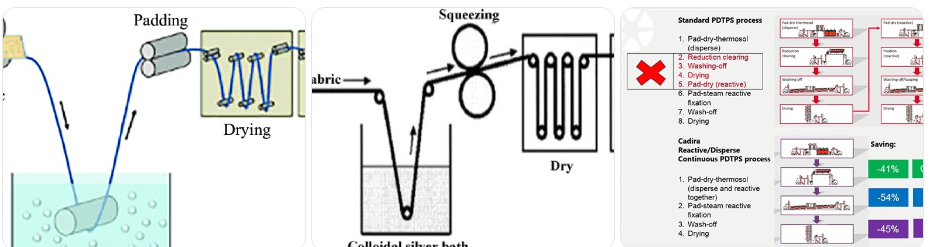

Method 2: Cold Pad Batch (CPB) Dyeing

Where It Works Best

Woven cotton, sheeting, shirting, terry towels.

Mechanism

High pad pick-up + controlled batching in cool conditions slow hydrolysis and improve fixation efficiency.

Typical Process Window

| Parameter | Range |

|---|---|

| Temp | 20–25°C |

| P/U | 70–80% |

| Salt | 0–20 g/L (often salt-free) |

| Alkali | 10–25 g/L soda ash |

| Batch Time | 6–12 hrs |

Advantages

- Lowest cost per kg among all methods

- Minimal salt → best for sustainability (ZDHC/GOTS aligned)

- Low energy requirement

- Very high fixation

Limitations

- Not suitable for knits (creases, rope marks)

- Requires controlled batching (no temp rise)

- Long batch holding time

Best For

- High-volume sheeting

- Terry

- Shirting

- GOTS-compliant production

Method 3: Pad-Dry-Cure

Where It Works Best

Pigment-heavy shades, very dark shades on woven, where throughput matters.

Mechanism

High-temperature curing activates dye–cellulose reactivity (especially for HE, ME dyes).

Process Window

| Step | Typical Range |

|---|---|

| Drying | 100–120°C |

| Cure | 150–180°C (dye class dependent) |

Advantages

- Very high productivity

- Shortest process time

- Excellent penetration with modern dyes

Limitations

- Not ideal for bright shades

- Requires excellent stenter control

- Risk of shade variation if moisture varies

Best For

- Denim tops

- Workwear

- Heavy wovens

Method 4: Continuous Pad-Steam Method

Where It Works

High-volume woven plants with continuous dye ranges.

Mechanism

Moist heat fixes dyes rapidly while controlling hydrolysis.

Process Window

| Parameter | Range |

|---|---|

| Steam temp | 102–103°C (saturated) |

| Time | 1–3 minutes |

| Salt | 20–40 g/L |

| Alkali | 10–20 g/L |

Advantages

- Very high throughput

- Short dwell time → less hydrolysis

- Excellent reproducibility

Limitations

- High CAPEX

- Demands line discipline

- Requires stable pH & moisture profile

Best For

- Large fabric mills

- Towels, bed linen

- Solid shades at scale

Method 5: E-Control / Pad-Dry-Pad-Steam (PDP)Where It Works

Plants focused on energy savings, reduced wash-off load, and brand compliance.

Mechanism

Salt-free dyeing using controlled moisture addition just before steaming → reduces hydrolysis drastically.

Typical Parameters

| Parameter | Value |

|---|---|

| Drying | 110–130°C |

| Moisture addition | 15–25% |

| Steam | 102°C, 30–60 sec |

Advantages

- Salt-free → lowest environmental load

- Uniform fixation

- Very low M:L water use

Limitations

- Needs precision equipment

- Limited flexibility for shade depth

Best For

- GOTS / ZDHC aligned mills

- Mills reducing ETP burden

- Fashion/light shades continuous dyeing

Method 6: Semi-Continuous Pad-Dry-Batch

Where It Works

Highly versatile process between CPB and Pad-Steam.

Mechanism

Dyeing is padded, then dried, then batched with alkali added before batching.

Advantages

- Good for mills without steaming range

- More consistent than pure CPB

Limitations

- Crease marks if batching is not controlled

- Requires temp-stable batching room

Best For

- Medium-volume woven mills

- Towels & sheeting

Method 7: Modern Low-Salt / Salt-Free Reactive Systems

Mechanism

Dye structure is modified to increase intrinsic substantivity, reducing dependence on inorganic salts.

Typical Outcomes

- Salt reduction: 40–90%

- Lower COD/BOD by 20–40%

- Lower rewash water use

Advantages

- Best choice for ZLD plants

- Reduced scaling & machine corrosion

- Lower TDS load in ETP

Limitations

- Higher dye cost

- Sometimes lower shade brightness for deep shades

Best For

- Brands with strict RSL

- ZDHC-aligned dyehouses

- Regions with water stress

Comparison Matrix: Which Method Is Best for You?

| Method | Cost | Salt Use | Energy | Shade Depth | Best For |

|---|---|---|---|---|---|

| Softflow Exhaust | Medium–High | High | High | Excellent | Knits |

| CPB | Lowest | Very Low | Very Low | Very Good | Sheeting/Terry |

| Pad-Dry-Cure | Medium | Medium | Medium–High | Strong | Workwear |

| Pad-Steam | Medium | Medium | Low | Excellent | Large Mills |

| E-Control | Low | Minimal | Very Low | Good | Compliance-driven |

| Pad-Dry-Batch | Low | Low | Low | Good | Mid-volume mills |

| Low-Salt Exhaust | Medium | Very Low | Medium | Very Good | ZLD/ETP-sensitive |

Typical Problems & Diagnostic Checkpoints

A senior dyehouse would review these checkpoints systematically:

1. Low Fixation

- Check pH at alkali addition (target 10.5–11.5)

- Verify liquor TDS profile

- Check dye solubility at temp ramp

2. Shade Variation in Continuous Processes

- Moisture profile before steaming

- Pick-up variation ±2% max

- Alkali concentration at pad

3. High Rewash Demand

- Excess hydrolysis due to long alkali hold

- Poor rinsing sequence (first cold, then hot breaks)

- Check machine dead zones in softflow

4. High COD/BOD

- Excess salt

- Use of low-fixation dyes

- Inadequate neutralization after dyeing

Apart from these faults there is this dedicated article specifically for dyeing faults .

Sustainability & Compliance Considerations

Reactive dyeing is under scrutiny due to:

- High salt → TDS load

- High wash-off → COD/BOD

- Alkali discharge

- Energy & water consumption

Methods that strongly align with ZDHC, GOTS, OEKO-TEX, EU compliance:

- CPB

- E-Control

- Low-salt reactive dyes

- Continuous pad-steam with optimized wash-off

If selling to brands:

Always present “process-impact charts” showing TDS, COD, energy, and shade reproducibility.

Final Takeaways

- There is no single best method—the right choice depends on construction, shade depth, production scale, sustainability goals, and customer compliance demands.

- For knits → Softflow wins.

- For wovens & towels → CPB or Pad-Steam dominate.

- For sustainability leaders → E-Control and Low-salt systems are the future.

- The next 3–5 years will see rapid migration toward salt-free and low-water systems, especially in regions under ETP/ZLD pressure.

2 thoughts on “Different Methods of Reactive Dyeing of Cotton”

Comments are closed.