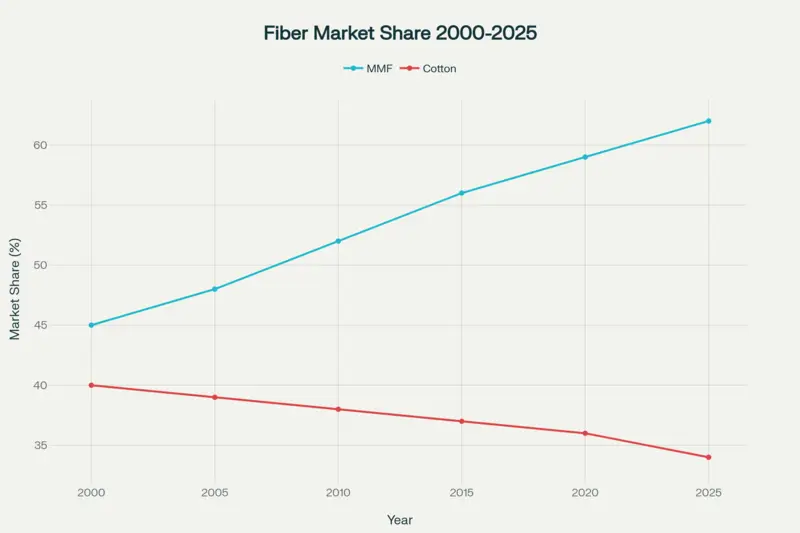

Manmade fibers (MMF) now dominate 62% of global output. Discover how this shift is transforming sourcing, spinning technology, and sustainability strategies.

The Synthetic Takeover

For decades, natural fibers like cotton and wool dominated the textile narrative. However, in the last twenty years, Manmade Fibers (MMF)—specifically polyester, viscose, and nylon—have quietly executed a takeover.

Today, MMFs account for nearly two-thirds of the world’s fiber output. This dominance is not just changing what we wear; it is reshaping the entire textile value chain, from raw material sourcing to garment recycling.

For mill owners and investors, understanding this shift is strategic. Fiber chemistry, feedstock sourcing, and energy profiles are now the primary drivers of competition and decarbonization.

Global Dynamics: The 62% Market Share

According to market data, manmade fibers now represent over 62% of global fiber production, led heavily by polyester. Polyester alone contributes approximately 54 million tonnes per year—an increase of nearly 300% since 2000.

The Regional Shift: Asia—specifically China, India, Indonesia, and Vietnam—accounts for the majority of this growth. This is driven by three factors:

- Lower Feedstock Costs: Proximity to petrochemical refineries.

- Integrated Infrastructure: Polymer-to-fabric manufacturing hubs.

- Export Demand: The global appetite for athleisure and performance wear.

Government policies are accelerating this. Initiatives like India’s PM-MITRA scheme are creating mega-parks where polymerization, spinning, and garmenting happen under one roof. This integration shortens supply chains and lowers logistics costs—a critical advantage in a low-margin industry.

The Chemistry Revolution: Beyond Standard Polyester

The MMF story is evolving beyond simple volume. The frontier is now Chemical Innovation.

- Recycled Polyester (rPET): Post-consumer bottles and textile waste are chemically recycled into virgin-grade fibers. Companies like Syre and Reliance are investing heavily in multi-kiloton recycling units.

- Bio-Based Polymers: Derived from castor oil, corn glucose, or sugarcane, these fibers reduce fossil dependency while maintaining performance.

- Regenerated Cellulosics: Innovations in Lyocell and Viscose (e.g., Spinnova, Renewcell) are transforming wood pulp and waste into fiber without toxic solvents.

Related Insight: See how these materials are utilized in specialized applications in our guide on What Are Technical Textiles? A Guide to the 12 Techs.

Supply Chain Impact: A Technical Transformation

The shift to MMF changes the technical requirements at every stage of production. It converts a linear agricultural chain into a circular chemical one.

Impact Across the Value Chain:

| Stage | Technical Shift Required |

| 1. – Feedstock | Move from farming contracts to chemical/polymer supplier relationships. Focus on Recycled vs. Virgin ratios. |

| 2. – Spinning | Continuous-filament yarns demand high-precision spinning and texturizing (DTY) machinery rather than ring frames. |

| 3. – Dyeing & Finishing | Shift to low-temperature dispersants and energy-efficient machines to reduce the thermal load of processing synthetics. |

| 4. – Recycling | Reverse logistics and sorting technologies become integral. Brands now demand data on Scope 3 emissions. |

Why MMF is Expanding Despite Sustainability Concerns

It seems counterintuitive: In an era of climate awareness, why are plastic-based fibers growing?

1. Resource Efficiency Synthetics require significantly less land and water than cotton. A polyester shirt does not require thousands of liters of irrigation water.

2. Durability & Functionality MMFs offer superior strength, wrinkle resistance, and moisture management. This extends the useful life of the garment.

3. Cost Scalability The production cost per kilogram is lower and, crucially, consistent. Unlike cotton, which fluctuates with harvest cycles, MMF prices are stable (though tied to oil prices).

However, fossil dependency and microplastics remain massive hurdles. This is driving R&D into Biodegradable Synthetics and filtration technologies.

Related Strategy: Learn how to manage the environmental impact of these materials in Reducing the Textile Carbon Footprint

Final Takeaway: The Circular Future

The next decade will see chemical recycling scale to millions of tonnes, fueled by Digital Product Passports that link fiber origin to the final sale.

The rise of manmade fibers isn’t just a material trend; it is the backbone of a new, circular textile economy. Manufacturers who adapt their spinning and finishing lines to handle these high-performance fibers will control the market.

Next Step: To understand how this shift affects your carbon reporting obligations, read our guide on Measuring the Textile Carbon Footprint.

For a broader view of where fiber fits into the total process, return to the The Modern Textile Manufacturing Value Chain: From Fiber Science to Factory Profit

Disclaimer

This article summarizes publicly available information for educational and industry awareness. Specific production figures are based on 2024-2025 market estimates.

4 thoughts on “How Manmade Fiber Growth is Reshaping the Textile Value Chain”