In textile processing, color fastness is not a laboratory ritual performed to satisfy buyers. It is a direct measure of how well chemistry, process control, and quality discipline have been executed on the shop floor. When garments bleed, fade, or stain other fabrics, the failure is rarely accidental. It is almost always predictable—and preventable.

The ISO 105 series, developed by the International Organization for Standardization, exists precisely to make these failures measurable, comparable, and actionable across mills, brands, and geographies.

This article explains ISO 105 in full—not as a checklist of tests, but as a decision framework that links laboratory results to real-world textile performance.

What ISO 105 Really Represents

ISO 105 is not one test. It is a family of standardized color fastness methods, each designed to simulate a specific stress that a textile encounters during use, care, or transport.

At first principles level, color fastness failure occurs when:

- Dye–fiber bonding is chemically weak or incomplete

- Unfixed or hydrolyzed dye remains on the fiber surface

- The dye system is unstable under light, moisture, pH, or ionic stress

ISO 105 does not improve fastness. It reveals which of these mechanisms is failing, under controlled and reproducible conditions.

Why ISO 105 Is More Critical Today Than Ever

Three structural shifts have made ISO 105 indispensable.

First, globalized supply chains demand standardized language. A mill in India, a buying office in Europe, and a testing lab in Bangladesh must interpret results identically.

Second, sustainability and compliance frameworks increasingly reference performance-based proof, not declarations. Passing ISO 105 tests consistently is indirect evidence of lower reprocessing, reduced effluent load, and controlled chemistry.

Third, fastness failures now translate directly into commercial risk—returns, claims, reputational damage, and loss of preferred supplier status.

ISO 105 is therefore not a lab formality. It is risk management.

The Structure of ISO 105: Understanding the Logic

Each ISO 105 part is identified by a letter corresponding to the type of stress applied.

| ISO 105 Section | Stress Simulated | What It Evaluates |

|---|---|---|

| ISO 105-C | Washing | Fixation + washing-off efficiency |

| ISO 105-X | Rubbing | Surface dye stability |

| ISO 105-B | Light | Photochemical stability of dyes |

| ISO 105-E | Perspiration | pH & ionic stability under sweat |

| ISO 105-D | Water / Sea Water | Bleeding under prolonged moisture |

Seen together, these tests cover process quality, end-use performance, and logistics robustness.

ISO 105-C: Washing Fastness — The Process Truth Test

Washing fastness is the most revealing test for dyed cellulosics, especially reactive dyed cotton.

Mechanistically, ISO 105-C exposes:

- Incomplete covalent bonding

- Excess hydrolyzed dye

- Poor detergent action or soaping temperature

- Inadequate liquor exchange

In practice, when a fabric fails ISO 105-C, the root cause is almost never “bad dye”. It is almost always poor washing-off discipline.

From an operational standpoint, ISO 105-C is a mirror. It reflects how well the dyehouse has managed:

- Alkali control

- Fixation time and temperature

- Post-dye washing sequence

Passing washing fastness consistently is a marker of process maturity.

ISO 105-X: Rubbing Fastness — The Surface Integrity Test

Rubbing fastness evaluates color transfer caused by mechanical friction, both dry and wet.

The underlying mechanism is surface-localized dye. This may result from:

- Poor migration during dyeing

- Over-shading compensated by weak washing

- Incompatible softeners or finishes

- Excess electrolyte carryover

A key insight is this:

A fabric can pass washing fastness but fail rubbing fastness. That indicates the problem is not bonding, but surface cleanliness.

Treating rubbing failures with fixatives without addressing root causes often creates new issues such as harsh hand feel, shade change, or reduced absorbency.

ISO 105-B: Light Fastness — The Dye Selection Test

Light fastness testing simulates prolonged exposure to UV and visible radiation.

Unlike washing and rubbing, ISO 105-B is not process-forgiving. No amount of perfect dyeing can compensate for a chromophore that is inherently light-unstable.

Failures here point directly to:

- Incorrect dye class selection

- Inadequate shade engineering for end use

- Misalignment between product application and performance expectation

For upholstery, automotive, outdoor, and home textiles, ISO 105-B must be considered at the recipe design stage, not after production.

ISO 105-E: Perspiration Fastness — The Skin-Contact Reality Check

ISO 105-E evaluates color fastness under acidic and alkaline sweat conditions, combined with moisture and heat.

From a chemical perspective, perspiration introduces:

- Ionic salts

- Organic acids

- pH shifts that alter dye solubility and fiber charge

This explains why a fabric can pass washing fastness yet fail perspiration fastness.

Operationally, ISO 105-E failures often indicate:

- Residual unfixed dye

- Inadequate neutralization after dyeing

- pH-sensitive dye–fiber systems

This test is critical for sportswear, innerwear, baby garments, and summer knits, where skin contact and claims risk are high.

Chlorine fastness ( ISO 105 E-03) is not missing by accident; it is deliberately not treated as a “universal” fastness stress within ISO 105.The ISO 105 family was structured around ubiquitous, unavoidable stresses that any textile may face during normal use, care, or transport. These stresses are environmentally universal. Every garment, regardless of market or application, will encounter them.

Chlorine exposure is fundamentally different. it is use case specific.

ISO 105-D: Water and Sea Water Fastness — The Logistics Test

ISO 105-D simulates prolonged exposure to water without mechanical action.

This test reveals a different failure mode:

- Dye migration due to capillary action

- Bleeding during wet storage or transport

- Shade instability under humid conditions

Because there is no detergent or abrasion, ISO 105-D catches problems that washing tests may miss—especially in dark shades and high dye load fabrics.

From a supply-chain perspective, ISO 105-D is essential for:

- Export garments

- Long sea transit

- Humid storage environments

Failing this test often results in staining complaints that appear outside the dyehouse, making root-cause analysis harder and costlier.

Assessment Methodology: The Grey Scale Discipline

All ISO 105 tests rely on standardized Grey Scales for:

- Color change

- Color staining

Using correct, well-maintained grey scales under controlled lighting is non-negotiable. Subjective grading, poor illumination, or aged scales undermine the integrity of the entire system.

Consistency here is as important as chemistry.

ISO 105 as a Sustainability Indicator

There is a strong, often overlooked link between ISO 105 performance and sustainability.

Poor fastness usually correlates with:

- Excess dye usage

- Higher water and energy consumption due to reprocessing

- Increased COD and color load in effluent

Mills that consistently pass ISO 105 tests tend to operate with cleaner processes, tighter controls, and lower environmental footprint—even before formal sustainability audits.

A Practical Mental Model for Using ISO 105

Think of ISO 105 as a stress map:

- Fails washing → fixation or washing-off problem

- Fails rubbing → surface contamination problem

- Fails light → dye selection problem

- Fails perspiration → chemical hygiene problem

- Fails water → logistics and moisture stability problem

This shifts ISO 105 from a buyer-imposed hurdle to a continuous improvement tool.

Final Takeaway

ISO 105 is not about passing tests. It is about understanding why fabrics fail in real life and correcting those weaknesses at the right stage—recipe design, process control, or finishing.

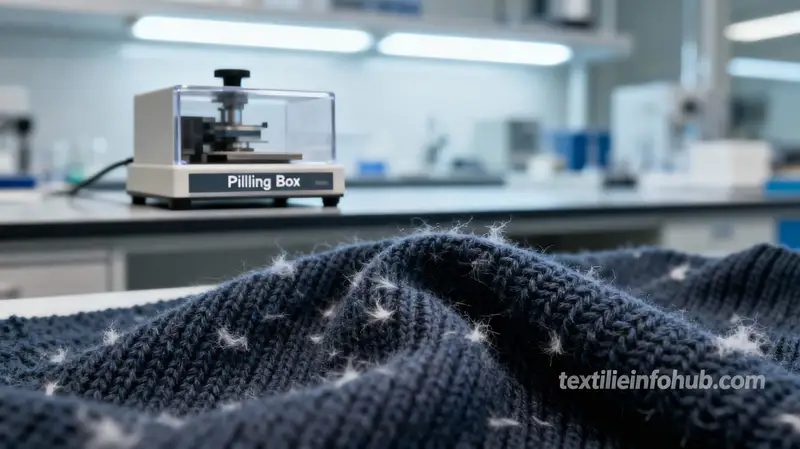

Mills that use ISO 105 as feedback, rather than fear, build stronger quality systems, reduce hidden costs, and earn long-term buyer confidence. The other two tests ISO 12945– Fabric Pilling and ISO 12947– Abrasion Test are also important to understand for quality that speaks for itself.