Master textile carbon footprint accounting. Learn to measure Scope 1, 2, and 3 emissions and why global brands mandate this data for supplier contracts.

The Metric That Defines Market Access

Have you ever calculated exactly how much carbon your business contributes to the atmosphere? For those in the textile supply chain, this is no longer a theoretical question—it is a critical business metric.

Knowing your company’s carbon footprint is the first step in managing a massive operational risk. It helps you quantify the impact of your entire operation, from the raw cotton bales to your factory’s boiler efficiency.

This guide breaks down the technical basics of measurement (Carbon Accounting) and explains why it is no longer optional for export-oriented mills.

Defining the Business Carbon Footprint

A business’s carbon footprint is the total amount of greenhouse gas (GHG) emissions caused directly and indirectly by its activities. It is typically measured over a fiscal year and expressed in tonnes of CO₂-equivalent (CO₂-eq).

This isn’t just about what you burn in your own factory; it is a comprehensive audit of your entire value chain.

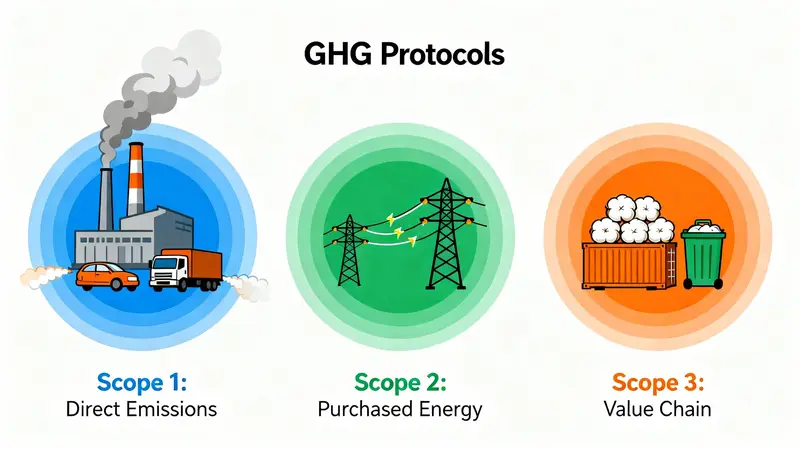

For industry professionals, the concept is governed by the GHG Protocol (the global standard), which divides emissions into three distinct “Scopes.”

The Accounting Framework: Understanding the 3 Scopes

You cannot calculate a textile mill’s footprint with a simple online calculator. The process involves a rigorous “Carbon Inventory” that maps every energy source.

Scope 1: Direct Emissions These are emissions from sources that your company directly owns or controls.

- Stationary Combustion: The natural gas, coal, or furnace oil burned on-site in your boilers, stenters, and dryers.

- Mobile Combustion: Fuel burned by company-owned vehicles (trucks, forklifts, executive cars).

- Process Emissions: Chemical reactions during manufacturing that release GHGs (less common in textiles, but relevant in fiber production).

Scope 2: Indirect Emissions (Purchased Energy) This is often the largest source for spinning and weaving mills.

- Purchased Electricity: The emissions generated off-site by the power plant that feeds your grid.

- The Reality: Even if your machines are electric, you have a massive Scope 2 footprint if your local grid runs on coal.

Scope 3: Value Chain Emissions This is the most complex category and typically accounts for the majority of a textile product’s total impact.

- Upstream: The “embedded” carbon in the goods you buy (e.g., polyester yarn, dyes, packaging) and the transport of those materials to your gate.

- Downstream: The transportation of your finished fabric to the customer and the eventual “end-of-life” disposal (landfill/incineration).

The Business Case: Economy Over Ecology

For a textile business, carbon accounting is not just an environmental exercise. It is a core strategy for survival.

1. Cost Reduction Carbon equals Energy, and Energy equals Money. A carbon footprint report is essentially a roadmap to your biggest inefficiencies. Identifying a “carbon hotspot”—like an inefficient coal boiler—is the fastest path to lowering operational costs.

2. Brand Requirements Major buyers (Nike, H&M, Patagonia) are aggressively tracking their own Scope 3 emissions. This means your emissions are their problem. If you cannot provide a transparent carbon data report, you will soon be ineligible to bid on premium contracts.

3. Future-Proofing Carbon taxes and “cap-and-trade” systems (like the EU ETS) are expanding. Businesses that do not measure their footprint will be blindsided by regulatory penalties.

Final Takeaway: Data-Driven Action

Calculating your footprint is the prerequisite for improvement. When you know that 70% of your impact comes from Scope 1 thermal energy, you know exactly where to invest your capital.

Next Step: Once you have measured your baseline, you must implement a strategy to lower it. Read our specific guide on Reducing the Textile Carbon Footprint: Strategic Decarbonization for Mills

To understand the broader context of sustainability in production, refer to the The Modern Textile Manufacturing Value Chain: From Fiber Science to Factory Profit

Thank you for the auspicious writeup. It actually used to be a amusement account it. Look advanced to far introduced agreeable from you! By the way, how could we be in contact?

свадебные платья официальный каталог свадебных платьев с ценами

купить провода силовые купить проводку для дома цена в минске

Нужны столбики? столбики ограждения столбики для складов, парковок и общественных пространств. Прочные материалы, устойчивое основание и удобство перемещения обеспечивают безопасность и порядок.

Looking for a yacht? affordable yacht charter Cyprus for unforgettable sea adventures. Charter luxury yachts, catamarans, or motorboats with or without crew. Explore crystal-clear waters, secluded bays, and iconic coastal locations in first-class comfort onboard.

заказать грузчиков заказать услуги грузчиков

заказ грузчиков стоимость услуг грузчиков

купить газоблоки цена газобетон цена

Google Salaries https://salarydatahub.uk by Role (US & UK) – Real Pay Ranges, Levels, and Total Compensation

кран шаровой под сварку кран приварной

Today’s Top Stories: this site

Looking for a yacht? Cyprus yacht booking platform for unforgettable sea adventures. Charter luxury yachts, catamarans, or motorboats with or without crew. Explore crystal-clear waters, secluded bays, and iconic coastal locations in first-class comfort onboard.

купить столбик ограждения мобильная стойка

магазин электрики кабель магазин электрики в минске

купить большое свадебное платье купить каталог свадебных платьев

Looking for a casino? pinup login is a licensed online casino with a wide selection of slots, live dealer games, and sports betting. New players can take advantage of a welcome bonus and regular promotions; deposits and withdrawals are available through popular methods. The site supports responsible gaming and offers customer support in multiple languages. Pinup Casino is suitable for players who prefer a user-friendly interface and a wide range of entertainment options.

ремонт у 1 5 квартирі ремонт квартир Львів

Mario games play online super mario bowser

Онлайн-журнал https://tga-info.ru со статьями обо всём: от технологий и финансов до психологии, бизнеса и лайфхаков. Читайте полезные материалы, обзоры, аналитические статьи и практические рекомендации для работы, обучения и повседневной жизни.

Онлайн-блог https://lifeoflove.ru о семейной жизни, психологии любви и гармоничных отношениях. Читайте статьи о доверии, понимании, воспитании детей, романтике и совместном досуге. Полезные советы и вдохновение для счастливой семейной жизни.

Интернет-журнал https://greendachnik.ru о садоводстве, огороде и ландшафтном дизайне. Полезные статьи о выращивании овощей, фруктов и цветов, уходе за растениями, планировании участка и создании красивого сада. Советы садоводов, идеи оформления и практические рекомендации.

Новости IT https://hardexpert.net и компьютерного мира: новинки технологий, программное обеспечение, гаджеты, компьютерные комплектующие и цифровые сервисы. Обзоры, аналитика, обновления программ и последние события в мире технологий.

Автомобильный портал https://hyundai-sto.ru со статьями обо всем, что связано с машинами. Новости автопрома, обзоры автомобилей, советы по выбору, ремонту и обслуживанию, сравнения моделей, технологии и полезная информация для водителей и автолюбителей.

Женский сайт https://allsekrets.ru о красоте, моде, здоровье и отношениях. Полезные статьи о стиле, уходе за собой, психологии, семейной жизни и саморазвитии. Советы, идеи и вдохновение для современной женщины, которая хочет выглядеть красиво и чувствовать гармонию.

Женский портал https://idealnaya-ya.ru о красоте, моде, здоровье и гармоничной жизни. Читайте статьи о стиле, отношениях, психологии, воспитании детей, саморазвитии и уходе за собой. Полезные советы, вдохновение и идеи для счастливой жизни.

Все о стройке https://dobdom.ru и ремонте: полезные статьи о строительстве домов, ремонте квартир, отделке помещений и выборе материалов. Советы специалистов, инструкции, идеи для интерьера и практические рекомендации по строительству и благоустройству жилья.

Портал о стройке https://profsmeta3dn.ru и ремонте: строительство домов, ремонт квартир, отделка помещений и современные строительные технологии. Полезные советы мастеров, обзоры материалов и инструмента, инструкции и идеи для ремонта и благоустройства жилья.

Found a bride? best spots for a romantic proposal in Barcelona romantic scenarios, beautiful locations, photo shoots, decor, and surprises for the perfect declaration of love. Make your engagement in Barcelona an unforgettable moment in your story.

Проблемы с застройщиком? взыскать неустойку с застройщика дду помощь юриста по долевому строительству, расчет неустойки, подготовка претензии и подача иска в суд. Защитим права дольщиков и поможем получить компенсацию.

Ищешь кран? кран шаровый под сварку для трубопроводов различного назначения. Надежная запорная арматура для систем водоснабжения, отопления, газа и промышленных магистралей. Высокая герметичность, долговечность и устойчивость к нагрузкам.

Нужен юрист? защита интересов в арбитражном суде представительство в арбитражном суде, защита интересов бизнеса, взыскание задолженности, споры по договорам и сопровождение судебных процессов для компаний и предпринимателей.

стойкие духи женские https://elicebeauty.com/parfyumeriya/byudzhetnaya-parfyumeriya/filter/_o647/