Stop rejections due to fabric pilling. A technical guide to ISO 12945 testing methods, grading standards, and engineering pilling resistance from fiber to finish.

The “Fuzz” That Kills Brand Reputation

For a consumer, fabric pilling—those annoying small balls of fiber on a sweater—is a clear sign of cheap quality. For a manufacturer, it is a quantifiable defect that leads to expensive claim settlements and failed shipments.

Fabric pilling is arguably the most common surface defect in spun yarns, particularly in synthetics and blends. Unlike a tear or a stain, it develops over time, making it a “latent defect.”

For the Quality Control (QC) manager, relying on visual estimation is not enough. You must understand the physics of fiber migration and the specific ISO standards used to grade it.

The Science: Why Fabrics Pill

Pilling is a physical process where loose fibers migrate to the fabric surface due to friction, twist, and entangle into small balls.

It typically occurs in four distinct stages:

- Fuzz Formation: Friction pulls loose fiber ends to the surface.

- Entanglement: These loose fibers twist around each other.

- Growth: The pill becomes denser and anchors itself to the yarn.

- Wear-off: The pill eventually breaks off.

The Synthetic Problem: Synthetic fibers (Polyester, Nylon) have high tenacity (strength). Unlike cotton pills, which eventually break off during washing, synthetic pills stay anchored to the fabric. This results in a permanent, unsightly defect.

Related Insight: Understanding fiber properties is critical. Read more in our guide on How Manmade Fiber Growth Is Reshaping the Textile Value Chain.

Testing Standards: ISO 12945 Series

Global buyers typically demand testing under ISO 12945. However, there are different methods depending on the fabric type.

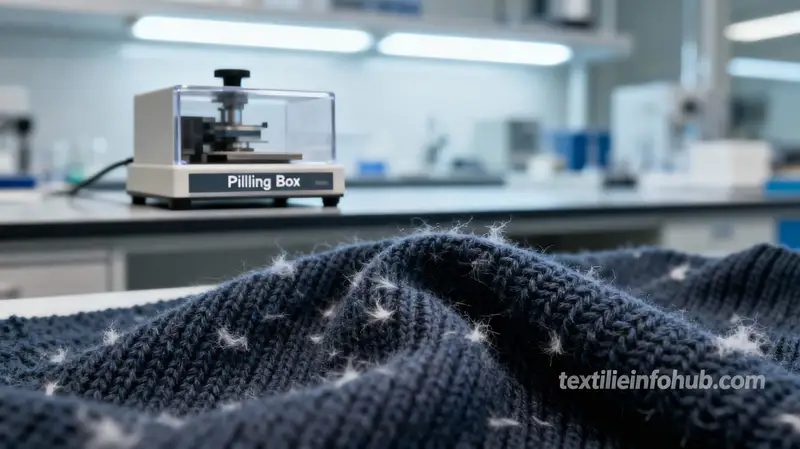

1. ISO 12945-1: The Pilling Box Method

- Best For: Knits and sweaters.

- Mechanism: Fabric specimens are mounted on polyurethane tubes and tumbled inside a cork-lined box.

- Action: The tumbling mimics the random friction of daily wear without applying heavy abrasive pressure.

2. ISO 12945-2: The Modified Martindale Method

- Best For: Wovens, upholstery, and workwear.

- Mechanism: This uses the same machine as abrasion testing but with a specific pilling attachment. The fabric rubs against itself or a standard wool abradant.

Comparison of Methods:

| Feature | Pilling Box (ISO 12945-1) | Martindale (ISO 12945-2) |

| Primary Use | Knitted Apparel / Sweaters | Wovens / Upholstery |

| Friction Type | Random Tumbling | Multi-directional Rubbing |

| Speed | 60 RPM | 47.5 RPM |

| Common Cycles | 14,400 revs | 2,000 / 5,000 / 7,000 rubs |

Engineering Pilling Resistance: A Fiber-to-Finish Approach

Pilling cannot be “cured” once it starts; it must be engineered out of the product during manufacturing. As a QC Manager, you must audit these four production stages.

1. Fiber & Spinning Strategy (The Root Cause)

Pilling is primarily caused by fiber migration—loose fibers slipping out of the yarn bundle.

- Staple Length: Use longer staple fibers. Short fibers (e.g., <26mm cotton) have fewer contact points in the yarn twist, allowing them to migrate to the surface easily.

- Low-Pill Synthetics: For polyester, specify “Low-Pill” variants. These fibers have lower tensile strength, ensuring that when a pill forms, it breaks off easily (like cotton) rather than anchoring permanently.

Spinning Technology:

- Ring Spun: Most prone to pilling due to high hairiness.

- Compact Spun: Significant improvement as aerodynamic condensing tucks in edge fibers.

- Vortex (MVS) Spun: The Gold Standard for pilling resistance (Grade 4-5). MVS yarn has a fasciated structure (parallel core, wrapped outer layer) that physically traps fibers, making pilling nearly impossible.

2. Fabric Construction Parameters

The physical structure of the fabric dictates how much friction the fibers experience.

- Knitting Tension: Loose structures pill faster. Increasing the Stitch Density (Tightness Factor) reduces the freedom of movement for yarns, minimizing surface friction.

- Weave Structure: In wovens, long floats (like Satins) expose more yarn surface to abrasion than tight structures like Plain Weaves or Twills.

3. Wet Processing: Prevention for Cotton

For cotton knits and wovens, the goal is to remove surface hairiness cleanly.

- Enzymatic Bio-Polishing: This is the industry standard for cotton knits.

- Chemistry: Use Acid or Neutral Cellulase Enzymes.

- Mechanism: The enzyme “eats” (hydrolyzes) the protruding micro-fibrils on the fabric surface without damaging the main yarn body.

- Result: A permanent reduction in hairiness and a cleaner look.

4. Wet Processing: Prevention for Synthetics

Synthetics are the biggest challenge because enzymes do not work on plastic, and the fibers are too strong to break off.

- Heat Setting (Critical): This is non-negotiable. Heat setting polyester (typically at 190°C – 200°C) stabilizes the crystalline structure of the fiber and the geometry of the knit loop. A well-set fabric prevents the yarn slippage that leads to fuzz formation.

- Anti-Pilling Resins: Apply acrylic or polyurethane-based binders during the padding stage. These resins form a microscopic film that “glues” the surface fibers to the yarn core.

- Avoid Silicone Overload: Excessive use of Macro-Silicone softeners reduces fiber-to-fiber friction, actually encouraging slippage and pilling. Use hydrophilic micro-emulsions instead.

Upgrade Tip: Applying these chemical finishes uniformly requires modern machinery. To upgrade your finishing line, check our Textile Processing Machine 2026 Buyer’s Guide

The Grading Scale (1 to 5)

Regardless of the machine used, the result is assessed visually in a Light Box against standard photographs (EMPA or ASTM standards).

- Grade 5: No change (Perfect).

- Grade 4: Slight surface fuzzing (Acceptable for most exports).

- Grade 3: Moderate pilling (Borderline rejection).

- Grade 2: Distinct pilling (Rejection).

- Grade 1: Dense pilling (Severe failure).

Final Takeaway: Test Early, Test Often

Pilling resistance is a Critical-to-Quality (CTQ) parameter. Waiting for a buyer claim is the most expensive way to discover a spinning flaw.

Ensure your lab is equipped with the correct ISO 12945 standard photographs, as subjective grading is a common source of dispute between mills and buyers.

Next Step:Now that you understand the testing, you need to manage the overall quality framework. Review the broader context in our The Ultimate Guide to Textile Manufacturing

One thought on “ISO 12945 Pilling Test Guide: Apparatus, Methods & Grading Ratings”

Comments are closed.