A technical Root Cause Analysis (RCA) of Common Dyeing Defects. We dissect the 5 costliest defects—Barre, Uneven Dyeing, Spots, Poor Fastness, and Crease Marks—with expert solutions for prevention and salvage.

The Cost of “Off-Shade”

In a textile mill, there is no sound more expensive than a QC manager saying, “This batch is rejected.”

A single dyeing defect is a catastrophic failure. It wastes thousands of dollars in water, energy, chemicals, and labor. It destroys your RFT (Right-First-Time) KPI and delays shipments.

This is not a basic “what is dyeing” guide. This is a technical Root Cause Analysis (RCA) of the 5 most common, high-stakes dyeing defects. We will go beyond the visual symptom and dig into the technical cause—whether it originates in the yarn, the machine parameters, or the chemical auxiliary—and provide the industry-standard solutions.

Defect 1: Barre (The Horizontal Stripe)

What It Is: A repetitive, horizontal stripe or band of a different shade running across the width of the fabric (weft/course direction). It is most common in circular knits and synthetic fabrics.

The QC Test: Visual inspection on a flat table under D65 lighting. The pattern is regular and repetitive.

Root Cause Analysis (RCA): Barre is almost never a dyeing fault. It is a fiber/yarn fault or a knitting fault that the dye reveals.

- Yarn Mixing: Using yarn from different spinning lots or merge numbers. These yarns have different dye affinities (uptake rates).

- Inconsistent Tension: Variations in texturizing tension (for polyester) or winding tension create physical differences in the yarn structure.

- Knitting Mechanics: A feeder set to a different tension or a stitch cam out of calibration creates a tighter or looser stitch loop, which reflects light differently.

The Solution (Prevention):

- Strict Lot Control: Never mix yarn lots in a single knitting run.

- Greige Inspection: Perform a “knit-dye” test on yarn cones before bulk production.

- High-Energy Dyeing: For polyester barre, dyeing at a higher temperature (135°C) with a specialized Barre Leveling Agent can sometimes mask the defect.

Defect 2: Uneven Dyeing / Shade Variation

What It Is: Also known as “patchy,” “cloudy,” or “unlevel” dyeing. The color is not uniform across the fabric width (side-to-center) or length (end-to-end).

The QC Test: Spectrophotometer reading (Delta E) across 5 points of the fabric width. Visual check for “cloudiness.”

Root Cause Analysis (RCA): This is a classic wet processing failure.

- Poor Pretreatment: The #1 cause. If scouring is incomplete, pockets of natural oils, waxes, or sizing remain on the fabric. These areas resist dye.

- Rapid Heating: The dye bath temperature was raised too quickly (high °C/min ramp rate). The dye “rushed” onto the fiber unevenly.

- Bad Circulation: The pump pressure or nozzle pressure in the jet dyeing machine was too low, causing poor liquor circulation.

The Solution (Prevention):

- Check Absorbency: Ensure the fabric is fully absorbent (drop test < 3 seconds) before dyeing.

- Control the Ramp: Use a machine controller to ensure a slow, controlled heating rate (e.g., 1°C/min) during the critical dye exhaustion phase.

- Leveling Agents: Use a high-quality leveling agent to retard the dye strike rate.

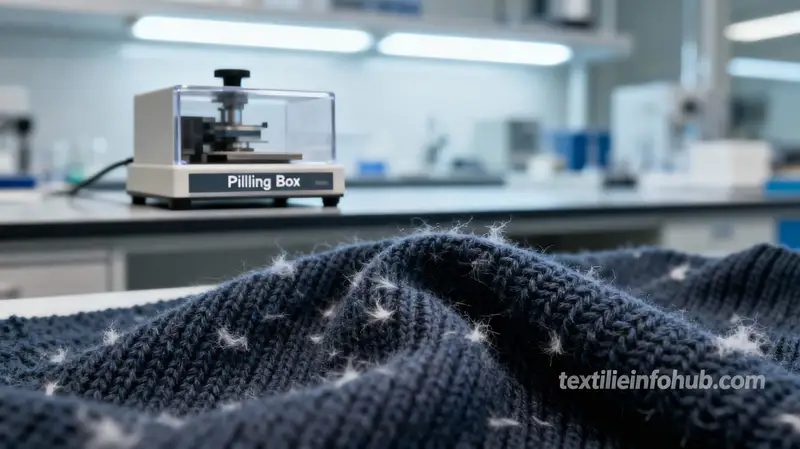

Defect 3: Dye Spots & Stains

What It Is: Small, distinct spots of concentrated color or “blotches” on the fabric surface.

The QC Test: Visual inspection. Spots are usually darker than the base shade.

Root Cause Analysis (RCA): This is a dissolving or compatibility problem.

- Improper Dissolving: Dye powder was not fully dissolved before being added to the machine.

- Dye Agglomeration: Hard water (high Calcium/Magnesium) or incorrect pH caused the dye molecules to clump together in the bath.

- Machine Contamination: Residue from a previous dark batch (e.g., Black or Navy) flaked off the machine walls.

The Solution (Prevention):

- Dissolve Correctly: Follow the manufacturer’s TDS for temperature and stirring time. Filter the dye solution before adding it to the tank.

- Soft Water: Ensure process water hardness is < 50 ppm. Use a sequestering agent if necessary.

- Boil-Out: Perform a rigorous machine cleaning cycle with caustic and hydro between dark and light shades.

Defect 4: Poor Color Fastness (Bleeding)

What It Is: The color washes out (bleeding) or rubs off onto other surfaces (crocking).

The QC Test:

- Washing Fastness: ISO 105-C06 / AATCC 61

- Rubbing Fastness: ISO 105-X12 / AATCC 8 (Crockmeter test)

Root Cause Analysis (RCA): The root cause is “unfixed dye.”

- Ineffective Washing: After dyeing, the fabric carries “hydrolyzed” (unreacted) dye on the surface. If this isn’t washed off properly, it will bleed later.

- Wrong “Soaping” Temperature: Reactive dyes on cotton require a boiling soap-off (95°C+) to remove loose dye. Doing this at 60°C is ineffective.

- Missing Reduction Clearing: For polyester, a reduction clear (chemical wash) is mandatory to remove surface dye.

The Solution (Prevention):

- Process Discipline: Do not cut corners on the washing/soaping cycle to save time.

- Fixing Agents: Apply a cationic fixing agent in the final bath to “lock” the dye molecule to the fiber.

Defect 5: Crease Marks / Rope Marks

What It Is: Random, spider-web-like lines or streaks on the fabric, usually lighter or darker than the base shade.

The QC Test: Visual inspection. The marks look like permanent wrinkles.

Root Cause Analysis (RCA): This is a mechanical and thermal fault.

- Thermal Shock: Cooling the dye bath too quickly (e.g., from 130°C to 80°C in 5 minutes) “shocks” the thermoplastic fiber (like polyester), setting permanent creases.

- Overloading: Loading the machine beyond its capacity prevents the fabric from “opening up” and changing position, leading to permanent rope marks.

The Solution (Prevention):

- Controlled Cooling: Use a slow cooling ramp (1.5°C/min). Never “crash cool” synthetic fabrics.

- Lubrication: Use an Anti-Creasing Agent (crease inhibitor) in the bath. This lubricant helps the fabric slide against itself and the machine walls.

- Load Correctly: Respect the machine’s nominal capacity.

Takeaway : Prevention is Cheaper Than Cure

Almost every dyeing defect is a process failure. It is a failure to control the raw material, the chemistry, or the machine parameters.

A Manager’s job isn’t just to catch defects; it’s to use data to prevent them. Moving from a reactive “fix-it” mindset to a proactive “root cause” mindset is the only way to improve your RFT rate and protect your margins. Right Pretreatment of cotton is first step towards RFT.

The journey from fiber to fabric is not just a linear chain; it’s a deeply interconnected ecosystem. To understand it deeply ,check our post on Textile Manufacturing : The Ultimate Guide From Fiber to Fabric

3 thoughts on “The 5 Most Common Dyeing Defects and How to Fix Them: A QC Manager’s Guide”

Comments are closed.