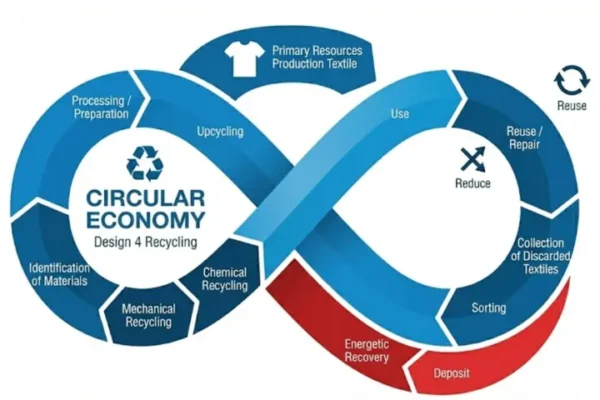

Circular Economy in Textiles: Regulatory Mandates & Market Scope

For Mill Owners and Textile Engineers, “Circularity” or Circular Economy is often dismissed as a buzzword or a marketing gimmick. This is a dangerous misconception. The transition from linear to a Circular Economy is a fundamental industrial shift, comparable to the adoption of automation in the 1990s. It is no longer a choice of “being…