A practical buyer’s guide for textile mills to choose the Right Textile ERP. We compare the pros, cons, and best-use cases for three main ERP solutions: Generalists (like SAP), Specialists (like Datatex), and Modular MES-first systems.

Introduction: The Breaking Point of a “Spreadsheet-Run” Mill

Your RFT (Right-First-Time) rate just came in at 75%. That means one-quarter of your dye batches are being re-processed, burning energy, water, chemicals, and profit.

Your top customer just called: a 10,000-meter batch of fabric they received has visible shade-banding. Your team is now scrambling through stacks of paper, trying to figure out which greige lots and dye lots were used.

You are blind. Your production plan is on a whiteboard, your inventory is in an Excel sheet that’s always out-of-date, and your true cost-per-meter is a complete guess.

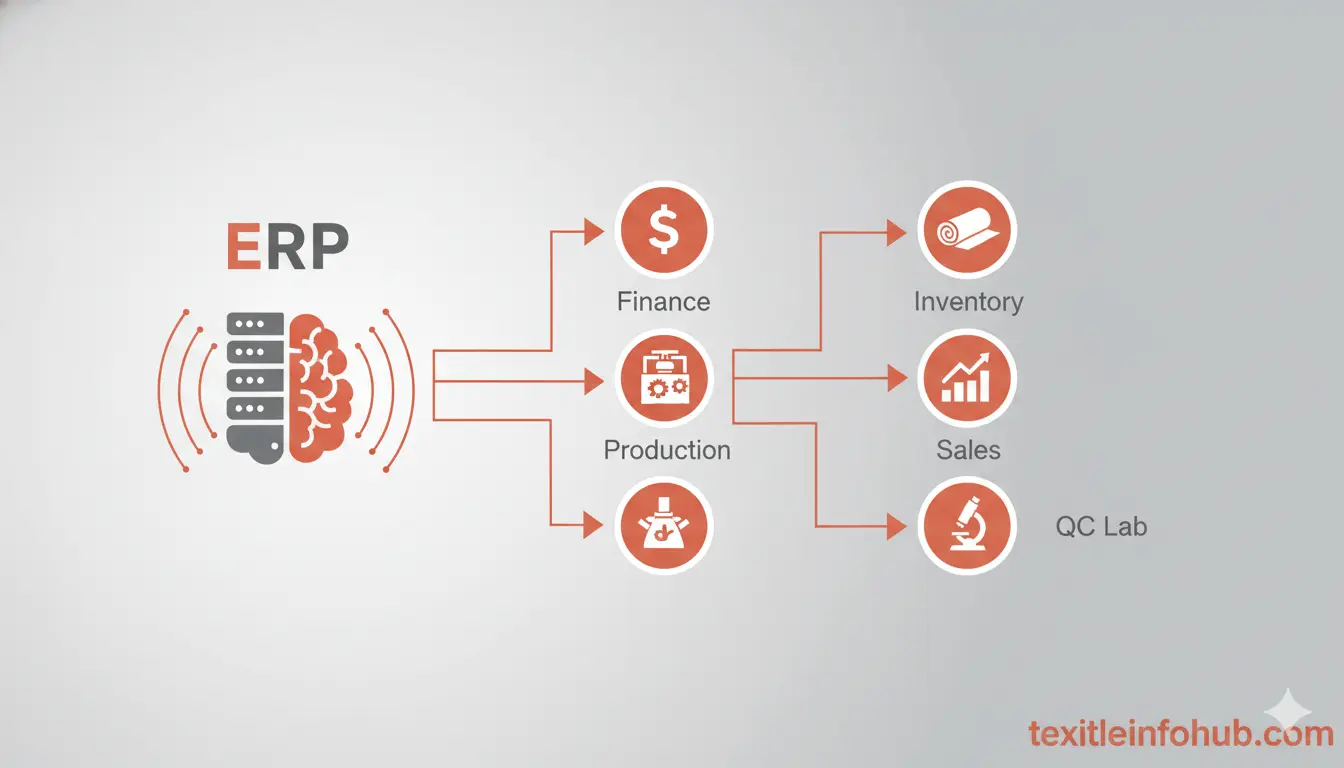

This is the breaking point. The “free” system of spreadsheets is now the most expensive thing in your company. You know you need an ERP (Enterprise Resource Planning) system—a “single source of truth.”

But the path forward is a high-stakes, high-cost minefield. Do you bet on a “generalist” giant like SAP and spend a fortune on consultants? Do you trust a “vertical specialist” like Datatex? Or do you just start with an MES like SEDO Treepoint to fix the factory floor?

This guide is a practical, pro/con comparison of the three main paths. We’ll analyze them not on marketing, but on their real-world ability to solve the unique, complex problems of a textile mill.

The Core Challenge: Why a Textile Mill Is Not a Car Factory

Before you can buy, you must understand why textiles are a special case. A generic ERP (like one built for assembling cars) is a “discrete” system. It understands: 1 Part A + 1 Part B = 1 Product C.

A textile mill is a “process-based” and “attribute-based” industry. A generic ERP will fail because it cannot understand three critical things.

1. Attribute-Based Inventory (The “Shade Problem”) A generic ERP tracks SKU 123 | Qty: 100 rolls. A textile ERP must track much more detail: Product, Greige Lot, Dye Lot, Shade (and its deviation), Width, and Grade. This shade-lot management is non-negotiable for quality and traceability.

2. The Recipe-Based BOM (Bill of Materials) A normal BOM is a static parts list. A textile BOM is a dynamic, percentage-based chemical recipe (dyes, auxiliaries, water, steam) that changes based on the fabric’s weight and the machine’s liquor ratio.

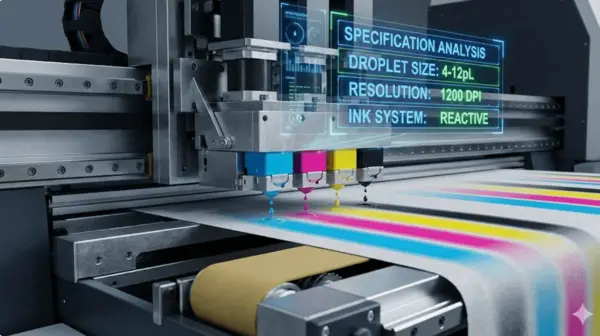

3. The Bill of Process (BOP) The cost and quality of a fabric are defined by the process itself (e.g., dyeing machine #2, 130°C for 60 min, followed by finishing X). This data must be captured, often from the machines directly.

The Three Solutions: A Pro/Con Comparison

Here are the three main solutions, from the “all-in-one” to the “build-it-yourself” approach.

Path 1: The All-in-One Specialist ERP

Best For: Small-to-large-sized mills (SMEs) whose primary business is textiles. Examples: Datatex, Aptean, CGS BlueCherry

Pros:

- Speaks Textiles Out-of-the-Box: This is their biggest advantage. They are built from the ground up to handle shade-lot management, recipe-based BOMs, and roll traceability.

- Faster Implementation: Because the system already aligns with 90% of your business processes, implementation is a “configuration” task, not a “customization” one.

- Lower Total Cost of Ownership (TCO): You spend less on external consultants because the software already does what you need it to do.

Cons:

- Weaker Non-Core Modules: Their Finance or HR modules are functional, but generally not as powerful as a global giant like SAP.

- Vendor “Lock-in”: You are investing in one company’s complete ecosystem. This can make it harder to integrate other, third-party tools.

- Less Known (Outside Textiles): Your brand partners (like H&M or Adidas) may not be familiar with your ERP, which can be a minor hurdle in data integration.

Path 2: The “Best-of-Breed” Modular Approach

Best For: Small, highly specialized mills (e.g., a single dyehouse or finishing plant) or those with a very tight budget. Examples: A dedicated MES (like SEDO Treepoint) + a separate accounting system (like Tally, QuickBooks, Zoho).

Pros:

- Solves the Biggest Problem First: This is a brilliant, practical strategy. You buy a MES (Manufacturing Execution System) like SEDO Treepoint to get your factory floor chaos under control. This immediately improves efficiency and RFT.

- Low Upfront Cost & Fast ROI: You can implement an MES in a few months and see an immediate payback in reduced water, energy, and chemical waste.

- Flexibility: You can choose the best-in-class tool for each job (e.g., SEDO for the dyehouse, Tally for finance).

Cons:

- It is NOT a True ERP: This is the key tradeoff. You are not creating a “single source of truth.” Your sales, inventory, and finance data are still in separate systems.

- Creates New “Mini-Silos”: You now have a high-tech “silo” on the production floor and another “silo” in the finance office, with a limited data connection between them.

- You Will Outgrow It: As your company grows, the lack of true, single-point integration will become your new bottleneck.

Path 3: The Enterprise Generalist ERP

Best For: Multinational, multi-billion dollar corporations that are already running on it, or whose primary problem is global finance and HR across many different industries. Examples: SAP S/4HANA, Oracle, Microsoft Dynamics

Pros:

- World-Class Finance & Global HR: These systems are unmatched for managing global finance, multiple currencies, and complex HR across thousands of employees.

- A “Common Language” for Enterprise: Your B2B brand partners (like Adidas or H&M) probably use it, which can (in theory) make B2B integration easier.

- Stability & Support: You are buying from one of the largest, most stable software companies in the world.

Cons:

- The “Customization Trap”: This is the critical flaw. These systems do not speak textiles. You will spend a fortune (often 1-3x the ERP cost itself) on external consultants to build a custom textile module from scratch.

- Prohibitively Expensive & Slow: This is not a solution for 90% of textile mills. Implementation is measured in years, not months, and the total cost is often in the millions.

- Extreme Rigidity: These systems are notoriously difficult to change once implemented. You adapt your business to the software, not the other way around.

At-a-Glance Comparison

Here is a quick summary to help you decide.

Specialist ERP

- Best For: SMEs & Textile-First Mills

- Core Strength: Textile Operations (Dye Lots, Recipes)

- Key Weakness: Weaker Finance/HR

- Est. Implementation: 6–18 Months

Modular (MES-First)

- Best For: Small/Specialized Mills

- Core Strength: Factory Floor Control & Low Cost

- Key Weakness: Not a true, unified ERP

- Est. Implementation: 2–6 Months

Generalist ERP

- Best For: Multinational Corporations

- Core Strength: Global Finance & HR

- Key Weakness: Does not speak textiles; high cost

- Est. Implementation: 1–3+ Years

Conclusion: How to Make Your Decision

The right choice depends on your single biggest “pain point” and your budget.

- If your pain is global finance and HR across multiple countries and industries, you’ll be forced into Path 3 (SAP). You must budget heavily (in time and money) for the textile customization.

- If your pain is inventory chaos, production planning, and shade-lot management, your best long-term investment is Path 1 (a Specialist ERP).

- If your pain is only on the production floor (e.g., controlling your dye machines) and you have a limited budget, Path 2 (an MES-first approach) is a smart, practical way to start.

The goal isn’t to buy the “best” software; it’s to find the right solution for your business model, your budget, and your biggest, most expensive problem.

4 thoughts on “How to Choose the Right Textile ERP: A Guide for Mills of All Sizes”

Comments are closed.