Stop looking at brand logos.

The most expensive Digital Textile Printer will fail on the production floor if the chemistry does not match your substrate or if droplet physics cannot penetrate your fabric structure. This buying guide strips away marketing language and focuses on the three engineering parameters that actually decide Return on Investment (ROI): ink chemistry, print head physics, and media transport mechanics.

This is not a branding decision. Buying an industrial Digital Textile Printer is a process-engineering decision.

The Chemistry-First Approach: Selecting the Ink System

You are not buying a printer. You are buying a chemical process.

The most common buyer mistake in a Digital Textile Printer investment is prioritizing speed or head count over ink compatibility. Fabric type dictates ink chemistry, ink chemistry dictates fixation method, and fixation method dictates downstream equipment such as steaming, washing, or curing.

A mismatch here leads to predictable failures:

- Poor rub and wash fastness – ( ISO-105-C-06 & ISO-105-X12)

- Color bleeding or migration

- Excessively stiff hand feel that buyers reject

Selection Protocol: The Ink–Substrate Matrix

| Ink Chemistry | Target Substrate | Process Complexity | Primary Application |

|---|---|---|---|

| Reactive | Cotton, Viscose, Linen, Rayon | High (Print → Steam → Wash → Dry) | High-fashion apparel |

| Acid | Silk, Wool, Polyamide (Nylon) | High (Print → Steam → Wash → Dry) | Scarves, swimwear |

| Sublimation | Polyester (≥70% poly) | Low (Print → Heat press) | Sportswear, soft signage |

| Pigment | Cotton-poly blends, home textiles | Medium (Print → Dry → Cure) | Bedding, upholstery |

A Digital Textile Printer should never be selected before this matrix is finalized.

Tech Note: The “Universal Machine” Trap

Many suppliers claim their Digital Textile Printer is “hybrid” and can run multiple ink types. Technically true. Practically dangerous.

Switching from reactive to pigment inks requires:

- Full system flushing

- Replacement of filters and dampeners

- Downtime and high contamination risk

Industrial best practice is simple: one machine, one chemistry.

Viscosity Control & Degassing

Industrial print heads demand tight viscosity control, typically 4–6 cP at jetting temperature. Any serious Digital Textile Printer must include an inline degassing unit.

Why this matters:

- Dissolved air causes nozzle misfiring

- Air bubbles are the primary cause of nozzle dropouts during long production runs

If degassing is optional, the machine is not industrial-grade.

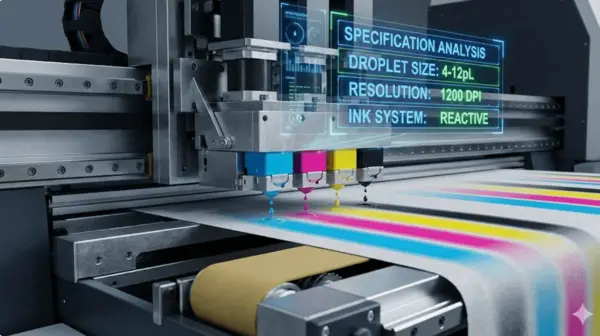

Print Head Physics: Droplet Size vs. Usable Resolution

Ignore “native resolution” numbers until you understand droplet size, measured in picoliters (pL).

In textile printing, sharpness and color penetration work against each other.

- Small droplets (4–7 pL)

- Excellent photographic detail

- Poor fiber penetration

- Causes “grinning” when fabric flexes

- Large droplets (14–40+ pL)

- Deep dye penetration

- Rich, solid colors

- Softer edges and reduced fine detail

Choosing a Digital Textile Printer without matching droplet size to fabric GSM is a specification error, not a quality issue.

The Specification Balancing Act

Fine Art, Silk, High-End Fashion

- Droplet size: 4–10 pL

- Priority: sharp lines, gradients, fine geometry

- Trade-off: limited backside penetration

Home Textiles, Pile Fabrics, Heavy Cotton

- Droplet size: 12–40+ pL

- Priority: saturation, through-print effect

- Trade-off: softer edges, less defined micro-text

Engineering Tip: Variable Drop Technology

Look for greyscale or variable-drop heads. These allow a Digital Textile Printer to fire multiple droplet sizes simultaneously.

Result:

- Sharp outlines from small drops

- Deep fills from larger drops

This is not a luxury feature. It directly affects sellable quality.

Media Transport Mechanics: Belt vs. Roller Systems

For knits, elastane blends, or lightweight fabrics, the transport system is non-negotiable.

Sticky Belt System (Mandatory for Apparel)

A sticky belt Digital Textile Printer uses a thermoplastic adhesive on a continuous conveyor to immobilize fabric.

Why this matters:

- Prevents fabric stretch and skew

- Eliminates edge curl

- Avoids catastrophic head strikes that destroy expensive print heads

Key inspection point:

The belt washing unit must fully remove lint and ink residues and re-activate adhesive in a single rotation.

If this system is weak, long-term stability is impossible.

Pinch Roller System (Limited Use)

Roller-fed systems rely on friction and tension.

Limitations:

- Distorts knits and elastane

- Causes cockling in thin fabrics

- High head-strike risk

Use cases:

- Stable heavy wovens

- Transfer paper for sublimation

A roller system Digital Textile Printer is unsuitable for fashion production.

Speed vs. Pass Rates: Calculating Real Output

Ignore advertised maximum speed.

Supplier datasheets usually quote 1-pass draft mode, which produces banding and unsellable quality.

Real production capacity must be calculated at sellable quality.

Example Calculation

- Claimed speed: 600 sqm/hour

- Required quality: 4-pass mode

- Actual output: 600 ÷ 4 = 150 sqm/hour

Critical question to ask every supplier:

“What is the linear meter output at 600 × 600 dpi, 4-pass mode?”

This single question exposes most exaggerated claims around Digital Textile Printer performance.

Hidden OPEX: Head Life and Maintenance Economics

CAPEX gets you installed. OPEX decides profitability.

The two largest ongoing costs in a Digital Textile Printer are:

- Ink price

- Print head replacement

Open vs. Closed Ink Systems

Closed (RFID-locked) systems

- Mandatory OEM ink

- 200–300% higher ink cost

Open systems

- Certified third-party ink sourcing

- Industry standard for profitability

Ensure the warranty explicitly supports approved third-party inks.

Recirculation and Negative Pressure

Industrial print heads are consumables, typically USD 2,000–4,000 per head.

A serious Digital Textile Printer must include:

- Through-flow ink recirculation

- Stable negative pressure control

Benefits:

- Prevents pigment sedimentation

- Reduces nozzle drying

- Extends head life significantly

Machines without recirculation will destroy heads prematurely, regardless of brand.

Final Thought: The Spec-Sheet Mental Shift

Buying a Digital Textile Printer is not an artistic choice. It is an engineering calculation.

Many machines look identical at exhibitions. On the production floor, their behavior is radically different.

Final Decision Checklist

- Chemistry Match

Does the ink system suit your exact fabric and end use? - Physics Check

Can the droplet size penetrate your fabric GSM without grinning? - Mechanical Check

Does the transport system prevent movement and head strikes? - Math Check

Is speed calculated at sellable pass rates, not draft mode?

If a Digital Textile Printer fails even one of these checks, no discount, subsidy, or brand reputation can make it a good investment.

Trust the parameters. Ignore the pitch.

You can find more interested articles in our Technology guide.

List of Major Digital Textile Printer Manufacturers for reference

Disclaimer: This list is informational only and does not imply ranking or endorsement. It is presented in Alphabetical order. Always evaluate each Digital Textile Printer model against the specifications defined in this guide.