Deciding between Air-Jet vs. Rapier looms for weaving technology? We break down the speed, yarn flexibility, energy costs, and ROI to help mill owners make the right 10-15-year investment.

The Loom Investment Dilemma: Choosing Technology for the Next 10-15 Years

Investing in weaving looms is one of the most financially decisive moments for any mill. A loom is not just another machine; it defines product capability, cost structure, energy consumption, efficiency levels, and the competitive position of your mill for the next 10–15 years.

In today’s market environment—where cost pressure, buyer expectations, fabric diversity, and rapid style changes are constant—selecting the right loom is more strategic than ever.

For most mills, the choice ultimately narrows down to Air-Jet or Rapier technology. Both are advanced, globally proven, and capable of high-quality production, but they are built on fundamentally different engineering philosophies.

- Air-Jets prioritize raw speed and lowest conversion cost per meter.

- Rapiers prioritize yarn flexibility, complex designs, and high-value production.

This technical guide explains the mechanism, performance indicators, energy impact, and cost factors so you can make a decision that aligns with your mill’s long-term goals.

Engineering Philosophies: Pneumatic Speed vs. Mechanical Grip

Before comparing productivity and ROI, understanding the physics behind each system is crucial to knowing why they perform differently.

Air-Jet Loom (Pneumatic Weft Insertion)

The weft yarn is carried across the width by high-velocity compressed air. The main nozzle fires the yarn into the shed, while auxiliary nozzles keep the yarn stable and on track throughout the width. Because no mechanical element crosses the shed, insertion is extremely fast. An Air-Jet loom is essentially “blowing” the yarn accurately across the warp field. This approach eliminates mechanical vibration at the weft level and allows extremely high insertion speeds.

Rapier Loom (Mechanical Weft Transfer)

Two rigid or flexible rapiers extend into the shed from both sides. The donor rapier grips the weft and hands it over to the receiver rapier at the center, which then completes the insertion. This controlled mechanical grip makes the Rapier loom capable of handling almost any yarn type. Rapier weft insertion relies on precision and control rather than raw speed.

Production Velocity and Output Efficiency Metrics

In large weaving mills, output per day per machine drastically affects profitability. Here is how the two technologies compare in a standard production environment:

| Feature | Air-Jet Technology | Rapier Technology |

| Weft Insertion | 1000–1600+ m/min | 600–900 m/min |

| RPM Range | 800–1200 RPM | 400–600 RPM |

| Primary Advantage | Unmatched Speed | Unmatched Versatility |

| Best Application | Shirting, Sheeting, Denim, Uniforms | Fashion, Jacquards, Upholstery, Technical |

The Takeaway: Because the Air-Jet loom has no physical weft carrier, its speed potential is unmatched. It excels in high-volume, cost-driven production. Rapier looms run slower due to the mechanical parts moving across the shed, but their precision supports high-margin fabrics where speed is secondary to complexity.

Yarn Versatility: Where the Real Trade-Off Happens

This is usually the deciding factor for mills targeting fashion or niche markets.

Air-Jet Yarn Capability

Air resistance affects yarn behavior; therefore, hairy or delicate yarns can misfire.

- Works Best With: Cotton, blends (PC, CVC), standard filaments, and combed/spun yarns.

- Limitations: Weak/hairy yarns, slub yarns, very coarse counts, slippery microfilaments, and usually limited to 2–4 weft colors.

Rapier Yarn Capability

The mechanical grip allows Rapiers to handle almost anything.

- Works Best With: Filament, textured, fancy yarns, slub, boucle, chenille, elastic yarns (Lycra), and technical materials (glass fiber, carbon).

- Capabilities: Can handle coarse high-denier yarns and 8–16+ weft colors.

For mills serving fashion brands or fast-changing designs, Rapier flexibility is often mandatory.

Fabric Esthetics and Selvedge Formation

Buyers often evaluate fabric quality by appearance, texture, and selvedge.

Air-Jet Quality Profile

- Excellent uniformity and consistent pick density.

- Clean tucked-in or leno selvedge.

- Ideal for mass-market woven fabrics where consistency is key.

Rapier Quality Profile

- Superior surface aesthetics for complex patterns.

- Multiple selvedge styles available: cut, tucked, or true selvedge.

- Excels in appearance-critical categories like fashion suits, curtains, ethnic wear, and Jacquards.

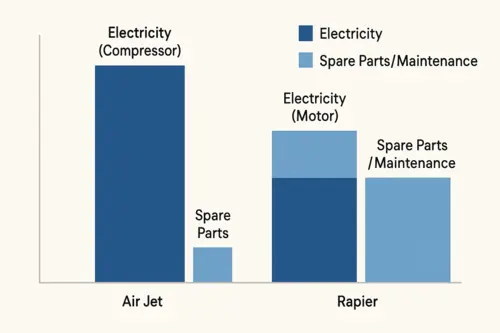

Operating Costs: Energy Consumption and Maintenance Loads

Energy cost is one of the largest recurring expenses in weaving, but the “source” of that cost differs between the two machines.

Air-Jet: The Pneumatic Cost

- High Energy Use: Relies on compressed air, requiring dryers, filters, and pressure regulators.

- Infrastructure: Air leakage dramatically increases costs. The compressor room is often the largest electricity consumer in an Air-Jet mill.

- Maintenance: Lower mechanical failures inside the shed, but higher maintenance on the air infrastructure.

Rapier: The Mechanical Cost

- Lower Energy Load: No compressors required; relies on motor power.

- Mechanical Wear: Higher friction means more wear on parts.

- Maintenance: Requires regular lubrication, timing adjustments, and mechanical upkeep.

Global Technology Leaders (Market Overview)

When selecting a machine, it is vital to consider the engineering strengths of major manufacturers. (Listed in no particular order of preference).

- Picanol (Belgium): Known for the OmniPlus-i (Air-Jet) and OptiMax-i (Rapier). Notable for electronic control integration and global service networks.

- Itema (Italy): Offers the R9500 (Rapier) and A9500 (Air-Jet). Frequently used in mills requiring stable weft transfer and innovation flexibility.

- Toyota (Japan): The JAT Series (Air-Jet) is a common sight in large-scale sheeting and denim mills, known for reliability and consistency.

- Dornier (Germany): Often positioned in the premium segment for both Rapier and Air-Jet, with a strong focus on technical and high-precision fabrics.

- Tsudakoma (Japan): The ZAX Series (Air-Jet) is widely utilized for its speed capabilities and fabric consistency in Asian markets.

The Decision Matrix: Matching Loom Type to Business Model

Choose Air-Jet If:

- Your business model is volume-driven.

- You produce standard constructions (Denim, Bed Linen, Shirting).

- Competitive cost-per-meter matters more than intricate fabric design.

- You have (or can build) a strong compressed air infrastructure.

- Production efficiency is your top KPI.

Choose Rapier If:

- Your market values design variety and complexity.

- You produce fashion, Jacquards, upholstery, or luxury fabrics.

- Yarn flexibility is essential (using fancy or technical yarns).

- You need multi-color weft capability (more than 4 colors).

- Your margins depend on fabric uniqueness, not just manufacturing speed.

Final Strategic Takeaway: Aligning Machinery with Mill Identity

Buying a loom is not only about technology—it’s about your mill’s identity.

Are you a volume producer competing on efficiency, or a design-driven mill competing on uniqueness and margin?

Many successful mills run a mixed approach: Air-Jets for mass volume lines and Rapiers for premium, high-margin fabric lines. Align your loom choice with your long-term product roadmap, yarn availability, air infrastructure, labor skill level, and future market expansion plans. The right loom becomes a competitive advantage for decades; the wrong one becomes an expensive constraint.

2 thoughts on “Air-Jet vs. Rapier Looms: Which is Best for Your Mill? – A Capital Investment Guide”

Comments are closed.